Problem :

Advanced manufacturing approaches to metal casting, thermoforming and mold making can utilize 3D printed parts for positive or negative impressions. Unfortunately, most 3D printers on the market today are inexpensive and do not have industrial qualities for larger production requirements.

Solution :

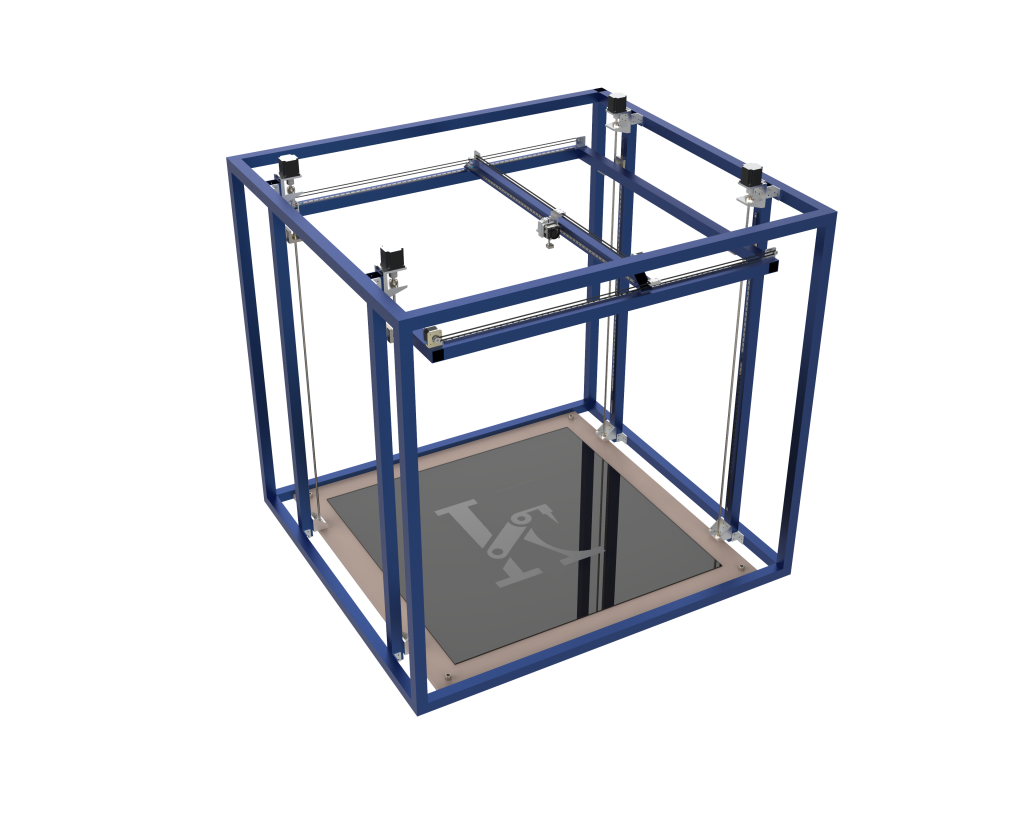

We designed a large build volume FDM 3D printer with some innovative features that set it apart from other 3d printers in the market.

Innovation :

Specifications :

- Build Volume: 1-meter x 1 Meter x 1 Meter.

- Type: FDM Polymer 3d printer with Cartesian Architecture.

- Extruders: MK8 Dual extruders

- Structure: Aluminum 6061 Profiles.

- BED: Non Heated Aluminum 6061 4mm/MDF

- Accuracy: 0.01 mm

- Repeat Accuracy: 0.015 mm

- Extruder nozzle diameter: 0.4 – 1 mm

- End stops: Inductive Proximity sensors

- Auto leveling sensor: Inductive proximity sensor

- Controller: MKS Gen 1.4

- Stepper motors: Nema 17 closed loop.

- X/Y axis drive: GT2 Pulley/Belt

- Z axis drive: Ball screws

- Filament runout sensor: Yes

- Overall weight of Printer: 60 kg